Marine HDPE Floats

HDPE floats widely used in various dredging projects, sand pumping projects, port expansion, channel dredging, channel and aquaculture industries.

HDPE Floats environmental adaptation of marine PE pipeline buoys: light a cigarette, place it flat on the surface of the buoy for five or six minutes, check the burnt part of the cylinder, if there are traces of burning, the high temperature resistance of the buoy is low, otherwise, it is strong;

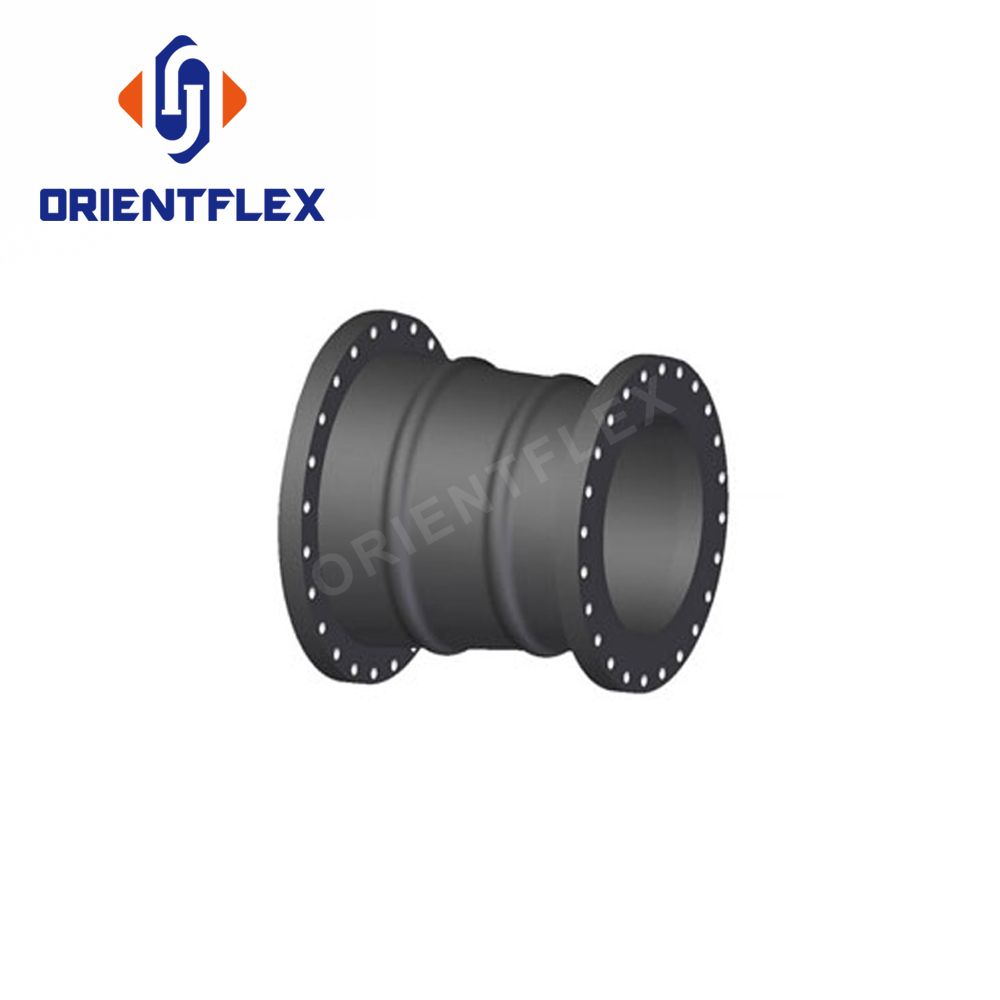

Marine HDPE floats

The gap tightness:For a platform assembled with good buoys, the cylinders are closely connected with each other, there is basically no gap, and a coin cannot fall down;

For a platform assembled with poor buoys, not only the gap is large, but the coin cannot be caught, and even through the The water surface can also be seen through the gap.

HDPE pipe floats applications:

Widely used in various dredging projects, sand pumping projects, port expansion, channel dredging, channel and aquaculture industries.

Features of marine HDPE floats:

1. Strong bearing capacity, stable and durable shell, each can provide 500kg buoyancy;

2. PE buoys are made of anti-corrosion, anti-freeze, anti-oxidation, and anti-purification reinforced materials, and are not eroded by sea water, chemicals, pharmaceuticals, oil stains, and aquatic organisms;

3. The assembly is simple, fast and flexible, and the circular and semicircular structures can be equipped with various pipelines;

4. This product has a long service life, except for strong natural forces and artificial improper use, there is no need to spend any maintenance fees, repair fees, etc.;

5. The shape is beautiful, and the surface of the buoy can be sprayed according to your specific requirements.

6. The cost is reasonable and economical. From a long-term point of view, it can save a huge amount of maintenance, maintenance, replacement and overhaul costs and time;

Marine PE pipe buoy details:

1. The product is molded at one time by rotational molding process, which is durable, light in weight, high and low temperature resistant, impact resistant, and has good sealing performance.

2. The sealing strip of the box is made of rubber, which is strong and durable, has excellent oxidation resistance, good elasticity and compression deformation resistance, and has the ability to resist ozone and corrosion;

3. Imported LLDPE material is selected, non-toxic and tasteless, anti-sun, anti-corrosion, anti-ultraviolet; corrosion-resistant, acid-alkali-resistant, easy to clean, good airtightness, and protects the internal equipment from chemical corrosion.

4. The box has good air tightness, high toughness and high resilience.

5. From the box material to the hardware, it is corrosion-resistant and can be shipped by sea to any place with a low temperature of -55°C and a high temperature of 70°C.

6. The R angle of the product formed by a special process is 15%-20% thicker than the surface, which proves that the material utilization efficiency is high and the drop resistance is very good.

7. Inside the box: positioning foam plastic buffer and shock absorption system, to ensure the safety and reliability of the carrier under vibration and bumpy conditions.

8. The color of the finished product is the color of the material itself, which is consistent inside and outside, and will not fade.

9. The maintenance is simple, the service life is long, and the comprehensive use is cost-effective.

| Specification | |

| floats | φ300*H800*B0re diameter of float 081 |

| φ400*H1000B0re diameter of float 050 | |

| floats | φ300*H1200*B0re diameter of float 050 |

| floats | φ300*H1070*B0re diameter of float 0120 |

| floats | φ300*H1000*B0re diameter of float 0125 |

| floats | φ300*H600*B0re diameter of float 096 |

| floats | φ300*H1000*B0re diameter of float 096 |

| floats | φ300*H1070*B0re diameter of float 096 |

HDPE Floats Install and Application:

Related Products

Get In Touch

Phone

+86 180 3185 3905

Address

Add: No.298 Zhonghua North Street ShiJiaZhuang, HeBei, China.